Laser cutting is using high power density of laser beam scanning the material surface, heat the material in a very short time to a few thousand to tens of thousands of degrees Celsius, and make the material to melt or gasify, The high pressure gas will blow away the melted or gasified material from the kerf to achieve the goal of cutting material.In the field of metal processing industry,it is a new cutting method.Traditional cutting technology can not meet the cutting efficiency and effectiveness as laser cutting machine.

Advantages of laser cutting machine:

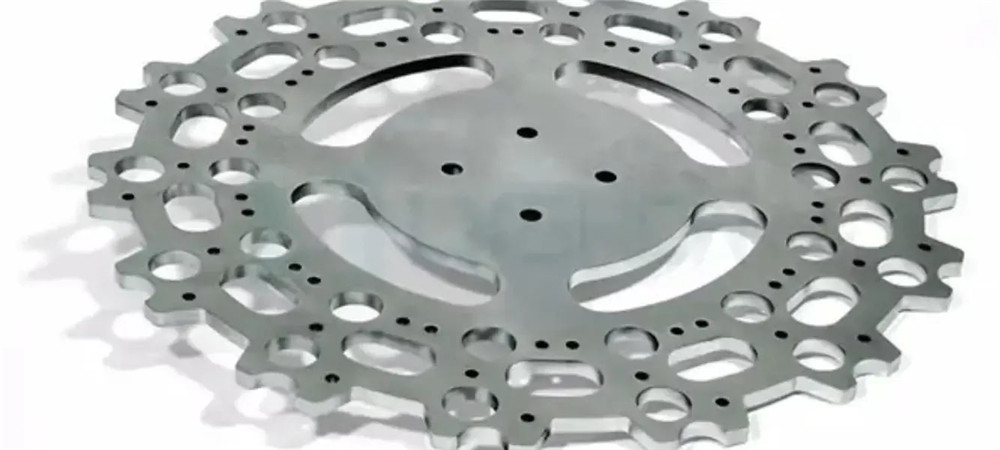

1. Fast speed, smooth and smooth incision, generally no subsequent processing;

2. Small cutting heat affected area, small plate deformation, narrow cutting seam;

3. The incision has no mechanical stress and no shear burr;

4. High processing precision, good reproducibility, no damage to the surface of the material;

5. Numerical control programming, can be processed arbitrary planar, can be a large format of the whole board cutting, no need to open the mold, economical and time-saving characteristics.

There are many kinds of materials that can be cut by laser, including plexiglass, wood board, plastic and other non-metallic plates, as well as stainless steel, carbon steel, alloy steel, aluminum plate and other metallic materials.

Because laser cutting can bring fast and precise cutting effect, it has no limitation to cutting materials, so it plays an increasingly important role in material processing, especially in metal processing industry.

For example,in the field of shipbuilding, especially special purpose boats, laser cutting has become a necessary means of processing, it is expected in the next 5-10 years, the production demand of this industry will be more and more large, the arrival of the era of "precision shipbuilding", indicates that the application of high-power CNC metal laser cut technology and equipment will be more and more extensive.

Europe Laser Cutting Machine Market

In the current metal processing market, fiber laser cutting machine and carbon dioxide laser cutting machine are the most widely used equipment, but fiber laser cutting machine is gradually replacing carbon dioxide laser cutting machine and the traditional means of processing,which become the mainstream equipment in sheet metal processing.So what are the differences and advantages of optical fiber laser cutting machine compared with carbon dioxide laser cutting machine?

1. Different luminous media.

Carbon dioxide laser cutting machine, gas is the medium to produce the laser beam, and transmits the beam through the mirror.Optical lasers work through diodes and fiber optic cables, where multiple diodes pump out the laser beam and transmit it to the laser cutting head via a flexible fiber optic cable rather than through a mirror.

2. More compact appearance of optical fiber laser cut.

Due to different laser transmission structures, optical fiber laser cutting machine with the same power in appearance size is more compact than carbon dioxide laser cutting machine, thus saving workshop space.

3. The conversion efficiency of optical fiber laser cutting machine is higher.

With the fiber laser complete solid state digital module, single design, fiber laser cutting machine has higher than carbon dioxide laser cutting electro-optical conversion efficiency.The actual utilization rate of each power supply unit of carbon dioxide laser cutting machine is about 8% to 10%, while the value of fiber laser cutting machine is about 25% to 30%. The overall energy consumption of fiber laser cutting system is about 3 to 5 times less than that of carbon dioxide cutting system, making the energy efficiency increase to more than 86%.

4. Fiber laser cutting machine processing effect is better.

Optical fiber lasers have shortwave properties that increase the absorbability of the cutting material to the beam and allow cutting of materials such as brass and copper as well as non-conductive materials.The cutting speed of 1.5KW fiber laser cutter is equivalent to that of 3kW carbon dioxide laser cutting machine when cutting materials with thickness of 6mm.

The Cutting Edge by Laser Cutter Is Smoother

5. The maintenance cost of optical fiber laser cutting machine is lower.

Carbon dioxide laser cutting machine uses gas as the luminous medium. Due to the purity of carbon dioxide gas, the resonator will be polluted, which needs to be cleaned regularly, and the mirror needs to be maintained and calibrated, so the daily maintenance work is more heavy.For a few kilowatts of carbon dioxide laser cutter, the cost is at least $20, 000 a year.In a word, the fiber laser cutting machine price is more environmentally friendly and convenient in the daily maintenance of equipment.

In the fierce industry competition, how to seize the opportunity to quickly improve product quality and production efficiency is a problem faced by every manufacturing practitioner. As the most efficient cutting equipment, fiber laser cut has been favored by more and more entrepreneurs and enterprises, providing more possibilities for the manufacturing industry.

As the largest manufacturer of laser application and intelligent equipment development in northern China.Xuzhou HaiBo CNC Technology Co.,Ltd.is the leading brand in innovation and upgrades of laser equipment and it aims to provide high quality service in the global laser intelligence.We have metal tube fiber laser cutting machine,laser sheet metal cutter,pipe-plate metal laser cutting machine,precision cutting fiber laser cutting machine and so on.We can provide you with the best solution according to your needs and power your business.

Post time: Mar-08-2022