A fiber laser cutting machine is mainly composed of the machine frame, the CNC system, transmission system, laser head and auxiliary system, most customers know little about other parts of the fiber laser cutting machine, but the choice of these parts is essential, which can influence the work efficiency of laser metal cutting machine.Let's take a look at what are the important components of a complete CNC fiber laser cutting machine, and how to choose these components.

Laser head

The cutting head of metal laser cut mainly includes cavity, focus lens, collimating mirror, cutting nozzle,ceramic ring and other parts, divided into manual focusing and automatic focusing, the cutting efficiency of automatic focusing is higher.Our company provides a number of brands of laser cutting head, you can choose the most suitable cutting head according to you own budget, Precitec,Raytool, WSX, Au3tech are good choices.

▲laser head of the fiber laser cut

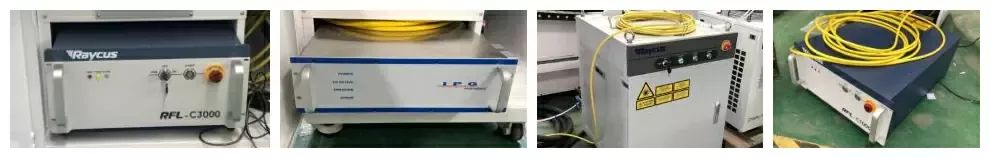

Laser generator

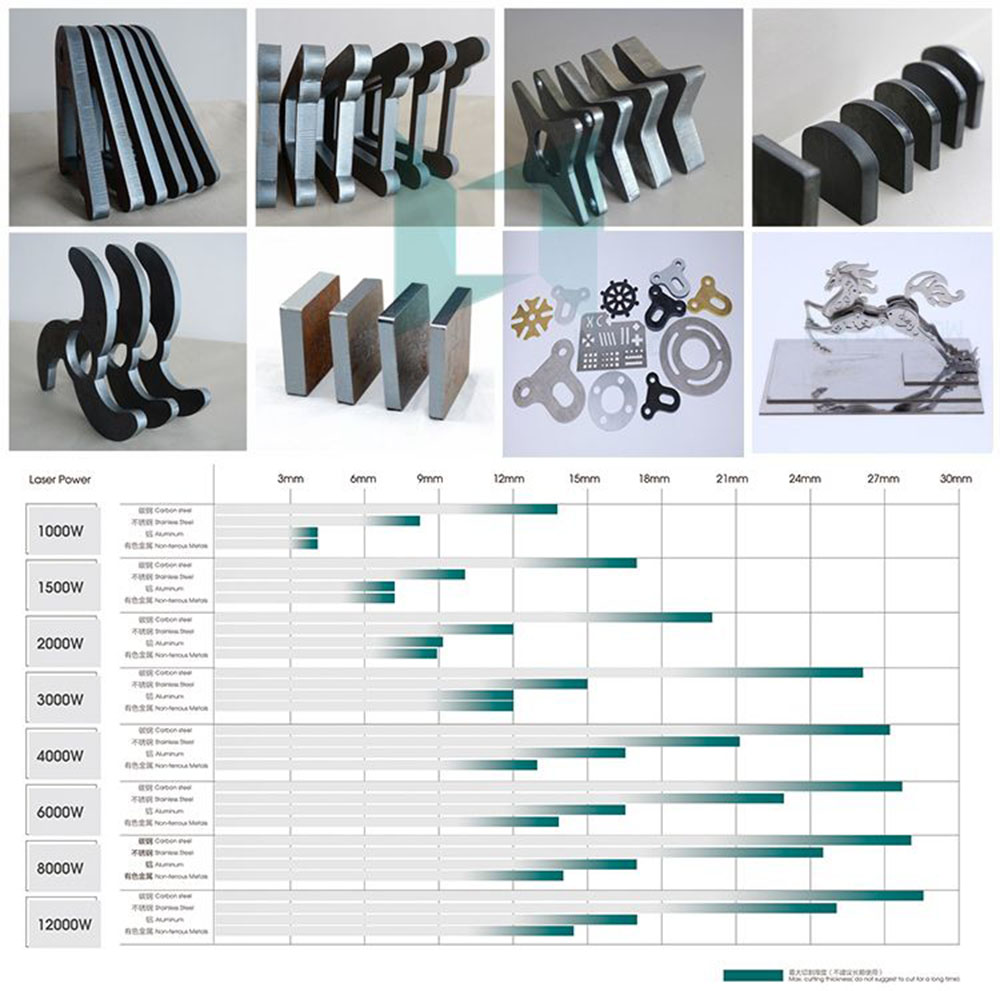

Fiber laser generator is the core component of fiber laser cutters, which is equivalent to the engine of a car. Compared with other types of laser, fiber laser has the advantages of high efficiency, long service life and low maintenance cost.Customers can choose the power of the generator according to the material they want to cut. At present, most of the high power laser steel cutting machine uses IPG laser generator. The performance of this brand in high power cutting is very stable.If the budget is limited or the need for small and medium power iron laser cutting machine, you can consider matching other brands, such as: Raycus, MAX, JPT, these brands is relatively high cost performance.

▲fiber laser generator of the fiber optic laser cutter

Air compressor

In order to achieve very high cutting quality and results,fiber laser metal cutting machine need clean, dry and stable air.The role of the air compressor is to provide part of the high-purity oxygen and high-purity nitrogen cutting gas to the cutting head, the other part is supplied to the cylinder of the clamping table as the power gas source, and the last part is used for blowing and cleaning the optical path system.The main source of air is mainly air compressor. The air compressor in the market is divided into piston type air compressor and screw type air compressor. The air compressor of CNC metal laser cutter should adopt permanent magnet frequency conversion motor, which can maintain the stability of air pressure and ensure the best cutting effect.

▲the air compressor of the metal fiber laser cutting machine

Auxiliary gas

metal laser cutter can use auxiliary gases are mainly air, nitrogen, oxygen and argon, the use of auxiliary gas in addition to blowing away the coaxial slit slag, but also can cool the surface of the processing object, reduce the heat affected zone, cooling the focusing lens, prevent smoke into the lens seat pollution lens and cause overheating.A lot of gas can be used generally, the focus should be on the cutting cost and the requirements of the product, such as cutting products later also need to be sprayed paint and other processing procedures, you can use air as cutting gas, to reduce costs.When the product is cut is the final product, there is no follow-up process, you need to use protective gas, so be sure to choose the gas according to the characteristics of the product.

1. Air

Air can be supplied directly by air compressors and is very cheap compared to other gases.There will be trace oxide film on the cutting surface, and the end face of the incision will turn yellow, but it can be used as a measure to prevent the coating from falling off.The main suitable materials are aluminum, aluminum alloy, stainless copper, brass, electroplated steel plate, non-metal and so on, but, when the quality requirements of cutting products are higher, it is not applicable.

2. Nitrogen

Some metals in the cutting when using oxygen will form an oxide film on the cutting surface, the use of nitrogen can be carried out to prevent the appearance of oxide film.Nitrogen cut cut end face white.The main suitable plates are stainless steel, electroplated plate, brass, aluminum, aluminum alloy and so on.

3. Oxygen

Mainly used for cutting carbon steel, the end face of the cut is black or dark yellow.It is mainly used for rolling steel, welding steel, mechanical steel, high tension plate, tool plate, stainless steel, electroplating plate, copper, copper alloy and so on.

4. Argon gas

Argon gas is an inert gas, used in fiber laser cutting machine to prevent oxidation and nitridation, can also be used for welding, compared with other processing gases, high price, cut end face white, the main suitable materials are titanium, titanium alloy.

▲the gas tank of the laser cutter for metal

Water chiller

Chiller is the equipment to ensure that the CNC laser cutter works under the condition of constant temperature equipment, fiber laser cutter machine in the process of processing will produce a lot of heat, if not timely cooling, will lead to laser parts overheating damage, chiller can be used to cool the laser.The power of the chiller is the same as that of the generator.

Problems to pay attention to in daily use:

1. Cleaning and water change: A inner circulating cooling water is deionized water (distilled water is best). It should be changed once every two months in summer and once every three months in spring, autumn and winter.B The deionization unit is changed every six months.Clean the tank and filter every six months.

2. The lower limit temperature of the temperature controller is generally set at 20℃, but in order to prevent excessive temperature difference and condensation, the working temperature is generally set according to the environment and humidity, such as the ambient temperature of 32℃, the lower limit temperature can be set at 28℃, and the upper limit temperature can be set at 35℃.If the ambient temperature is lower than 20℃, the lower limit temperature is set at 20℃.Generally not lower than 5℃ ambient temperature, otherwise condensation will lead to laser power decline, and may bring destructive losses.

▲the water chiller of the laser fiber cutting machine

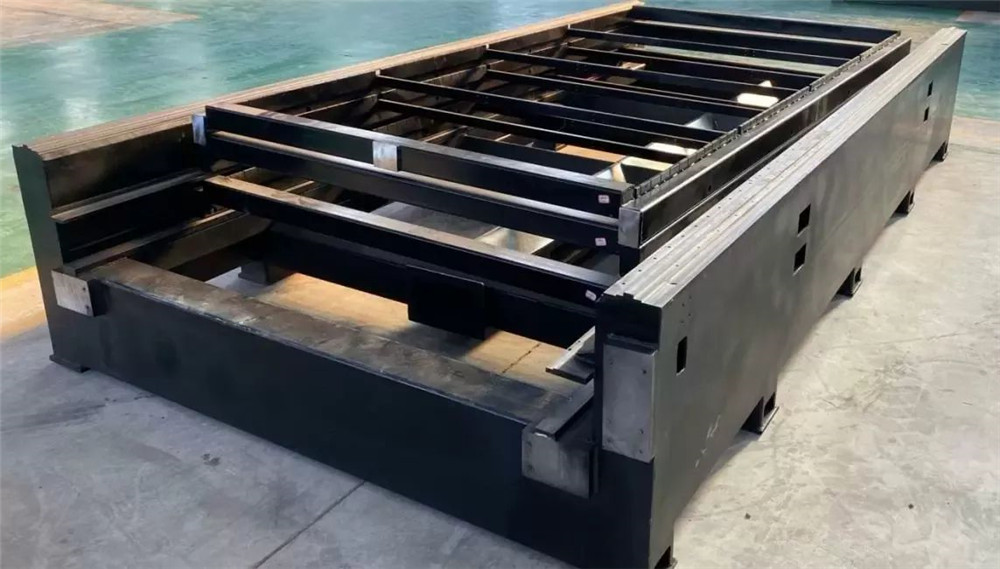

Machine frame

Machine frame is used to ensure that the fiber laser cutting machinery to achieve X, Y, Z axis of the stable mechanical movement of the device, used to put the cut workpiece, with the switchboard machine tool can also be in accordance with the control program correct and accurate movement, usually driven by a servo motor.In order to reduce cost,some manufacturer use a very thin sheet production machine shell,as time grows, the frame will be deformation, thus affecting the cutting precision of the iron cutter machine.So when you buy laser CNC machine,it’s necessary to see whether the optical fiber laser cutting machine’s shell is made by good quality materials such as iron.Our laser sheet metal cutter adopts steel bed, frame structure, the bed is welded by high quality steel, the fiber laser cutting machine cover is made of high quality cold rolled steel, durable, no deformation problem.

▲the machine frame of the CNC metal laser cutter

CNC system and software

The main body is a computer that controls the entire process of the cutting device, from which all the operational commands to control the optical fiber cutter are issued.The customer needs to know what system and software to install. The customer can choose the right cutting system and nesting software based on the power of the CNC laser metal cutter.Some programs have simple drawing capabilities, which can be useful if the design of the piece you need to cut is simple.

▲control card of laser cutter

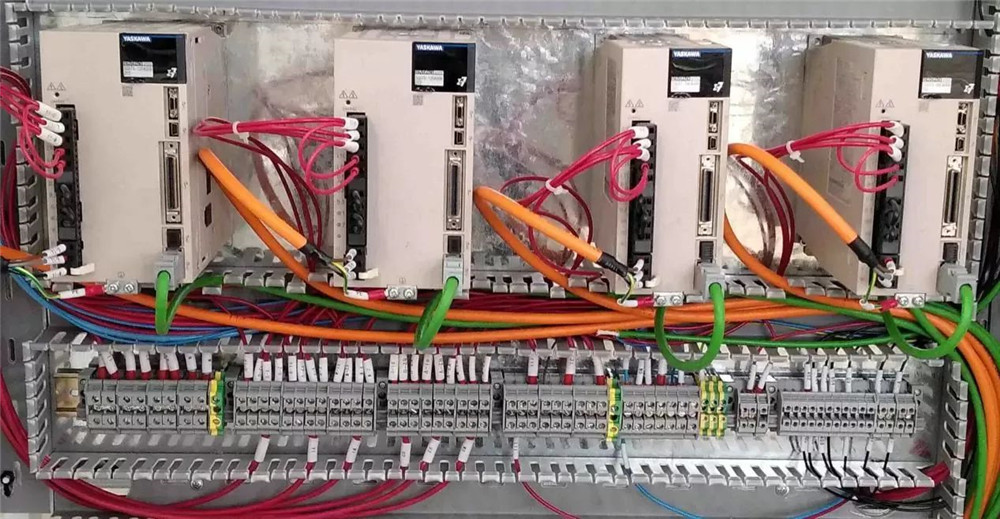

Servo motor

The main function of servo motor is to control the uniform and stable speed with the change of voltage, which is related to the operation precision of laser cutter machine.Our company provides customized service of metal laser cutting, there are many servo motor brands for you to choose, such as Yaskawa, Panasonic, Fuji, etc.

▲the servo motor of the metal CNC laser cutter

Exhaust fan and air cleaner

The fan can pump out the smoke and dust produced by laser cutting, and carry out filtration treatment, so that the exhaust gas emissions meet the environmental protection standards, will not cause pollution to the environment, the same effect of the air purifier.Customers can choose flexibly according to their budget, air purifier is better than the fan, but the price is also higher.The fan of the laser cutting machine for metal should be installed near the window to be effective. The power of the laser cutting dust collector should be selected within the power range of 5.5-13KW.

▲the cleaning fan of laser cutting metal machine

▲the air conditioner of CNC laser fiber cutting machine

Consumable parts

Mainly have focus lens, collimating mirror, protection lens, cutting nozzle, ceramic ring.Focus lens, collimating mirror and ceramic ring need to be replaced every 2 to 3 months. It is recommended that customers backup 5 lenses.The overall replacement frequency of the protective mirror is high. According to the different proficiency of the guests, the replacement frequency is different. Some users need to change it several times a day, and some change it only once in 7-15 days.According to the customer's cutting material and thickness, the corresponding cutting nozzle material and aperture should be selected. If the cutting nozzle is used for more than 500 hours, it is necessary to replace it. We suggest that the customer choose more aperture and backup 5 for each model.

▲the lens of fiber cutter machine

Now have you knew how to choose the fiber laser cutting machine accessories?If you still have no idea, you can consult the manufacturer's salesman to help you choose, they can comprehensively consider your budget and cutting requirements, to provide a most suitable for your program

Post time: Mar-08-2022