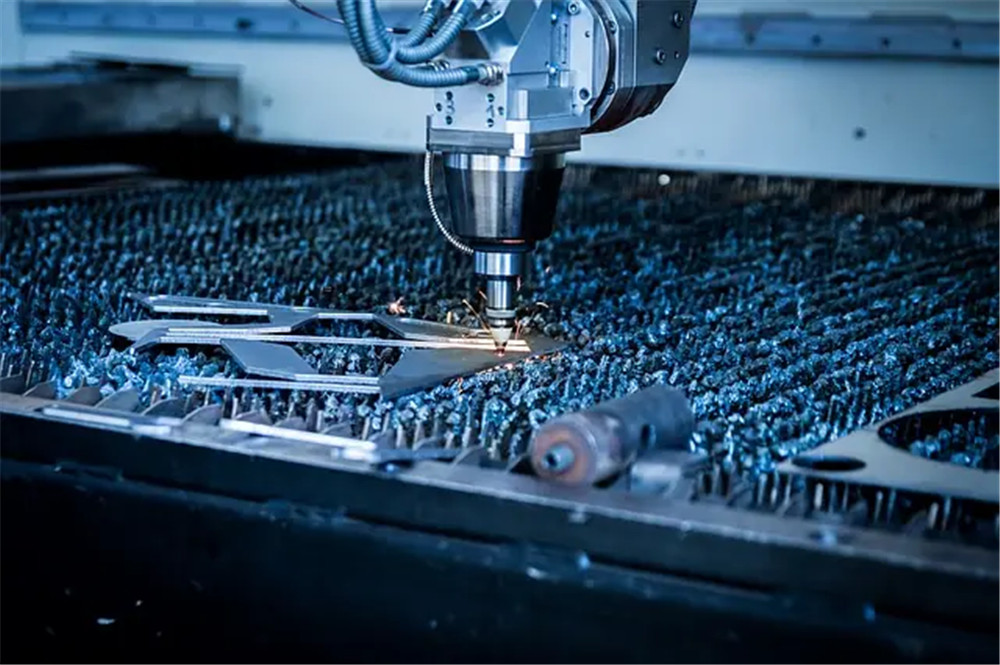

The rapid growth of metal laser cut market is mainly driven by the rapid development of material processing and information communication.Laser material processing is conducted in a non-contact way, with low energy consumption, high environmental benefits, high processing speed, low noise, little thermal impact, strong adaptability, and can process ultra-high hardness, high brittleness, high melting point materials, such as: metal and alloy, plastic, ceramics, glass, wood, leather, resin, rubber, etc.

▲fiber laser cutting machine for many kinds of products

●In the past decade, the compound growth rate of laser metal cutting machine revenue in the field of industrial applications is 35.50%, becoming the "new favorite" of industrial manufacturing.Fiber laser cutting machine can realize automatic control, and it has obvious advantages in precision machining, complex structure, batch automation production and other fields.Laser can be widely used in marking, punching, cutting, welding, sculpture and other industrial processing areas.Laser has been hailed as a "universal machining tools" and common processing means in the future manufacturing systems”.

● In 2020,laser power to cut metal has formed a pyramid layer. At the top of the pyramid, the ultra-high power fiber laser cut above 10KW occupies a minority, and the fiber laser cutting wattage requirements will become higher and higher.The middle and high power fiber optic laser cutter from 2KW to 8KW are currently the fastest growing areas.Bottom applications belong to the cutting market below 2KW.Back to the actual application, the output of ultra-high power metal cutting laser machine is not large, in the real application level, 2000-6000 watts’CNC fiber laser cutting machine of consumption is fast regression.

● In recent years, with the rapid development of the 3C industry, the frequency of product upgrading has been constantly accelerated, and higher requirements have been put forward for the production process of electronic products.Laser fiber cutting is one of the important technologies in 3C processing and application.Laser drilling can be used in mobile phones, laptops, PCB boards, headphones and other electronic products.In the past, the processing of 3C products uses traditional computerized gong processing technology. The material surface is easy to be convex, and burr problems occur frequently at the hole edge. However, the use of laser cutting machine for drilling can avoid such problems.Only need to set the layout and aperture of the drilling in the computer program, CNC metal laser cutter can precisely control the drilling parameters, make perfect round hole in a short time, greatly reduce the probability of reworking, therefore, fiber optic laser cutting machine in 3C product processing more and more favored.

▲fiber laser cutter is widely used in the 3C industry

●With the advent of commercial 5G, the market will produce a huge increase in circuit boards.Due to the larger amount of data, higher transmission frequency and wider working frequency band, the arrival of 5G era means higher requirements on the quantity and quality of antennas.With the wave of 5G base station construction, circuit board, as an indispensable electronic material in base station construction, will multiply in the future, which will also bring demand boost and more advanced processing technology requirements to the PCB board industry.Optical fiber metal laser cutting machine is a non-contact machining tool that can apply high intensity of light energy at a very small focus. It can be used for laser cutting, drilling, marking, welding, marking and other processing of materials.Its advantages in circuit board processing are mainly reflected in the following aspects:

1. Reduce production costs.The laser cutting circuit board adopts the numerical control processing form, does not need the mold processing, is helpful to save the mold expense, reduces the production cost.

2. Improve production efficiency.Laser processing speed, high precision, is conducive to directly shorten the product processing and manufacturing cycle, improve production efficiency.

3. Reduce unnecessary processing.Just import graphics into the control system of CNC fiber laser cutter, no matter how complex graphics, can be formed once, accurate implementation, can save unnecessary processing procedures.

4. no stress, no damage to the workpiece.Traditional contact processing method, will produce processing stress on the circuit board, may cause physical damage, fiber laser metal cutting machine processing circuit board non-contact processing, can effectively avoid processing material damage, deformation.

5. Low maintenance cost and high cost performance.Fiber laser cutting performance is stable, strong and durable, can work continuously, not easy to damage, in the late maintenance cost of great advantages.

metal and nonmetal laser cutting machine can cut metal and nonmetal

● Metal laser cutters are expected to create more jobs and bring more tax revenue to the government in the future.Slinger High School enables students to obtain more than 42 million construction, mining and manufacturing jobs in Wisconsin by introducing fiber laser cutters.They were the first high school in the country to use fiber optic laser cutter and the only high school in the state to use one.

▲IPG laser cutting machine in Slinger High School

●In 2020, the global sales volume of new energy vehicles soared. Among the 10 countries according to the statistics of Gasgoo, the sales volume of new energy vehicles in 8 countries reached 3-digit growth year-on-year, among which the market share of German new energy vehicles increased by 17.5% month-on-month, quadrupling that of last year. China's sales volume increased by 104.5% year-on-year, showing a great momentum of pure electric vehicles.After new energy vehicles enter the period of "rapid development", it can be predicted that advanced manufacturing technologies represented by laser technology will promote the rapid development of laser industry while constantly promoting the upgrading of automobile manufacturing industry.Especially as one of the main applications of the automotive industry laser cutting technology, its application prospect will be more and more broad.

Post time: Mar-08-2022