First, the plasma cutting machine has several cutting methods

Plasma cutting machine is a processing method of metal thermal cutting. Plasma cutting machine is a machine that processes metal materials with the help of plasma cutting technology.Plasma cutting machine has a variety of different cutting methods. The common cutting methods of plasma cutting machines are as following:

1. Ordinary cutting

According to the main working gas used,the portable cnc plasma machine is mainly divided into argon plasma arc cutting and oxygen plasma arc cutting. There are several types of oxygen plasma arc cutting and air plasma arc cutting. The cutting current is generally below 300A, and the cutting thickness is less than 30mm.

2. Re-constrained cutting

According to the re-confinement method of the plasma arc, the portable cnc plasma machine is mainly divided into water re-pressure plasma arc cutting, magnetic field re-confined plasma arc cutting, etc. Since the plasma arc is re-compressed, its current density and cutting arc energy are further concentrated, thereby improving the cutting speed and efficiency. Processing quality.

3. Fine cutting

The plasma arc current density is very high, usually several times that of the ordinary plasma arc current density. By introducing technologies such as rotating magnetic fields, the stability of the arc is also improved, so the cutting accuracy is quite high. The surface quality of foreign fine plasma cutting has reached the lower limit of laser cutting, and its cost is only one third of that of laser cutting.

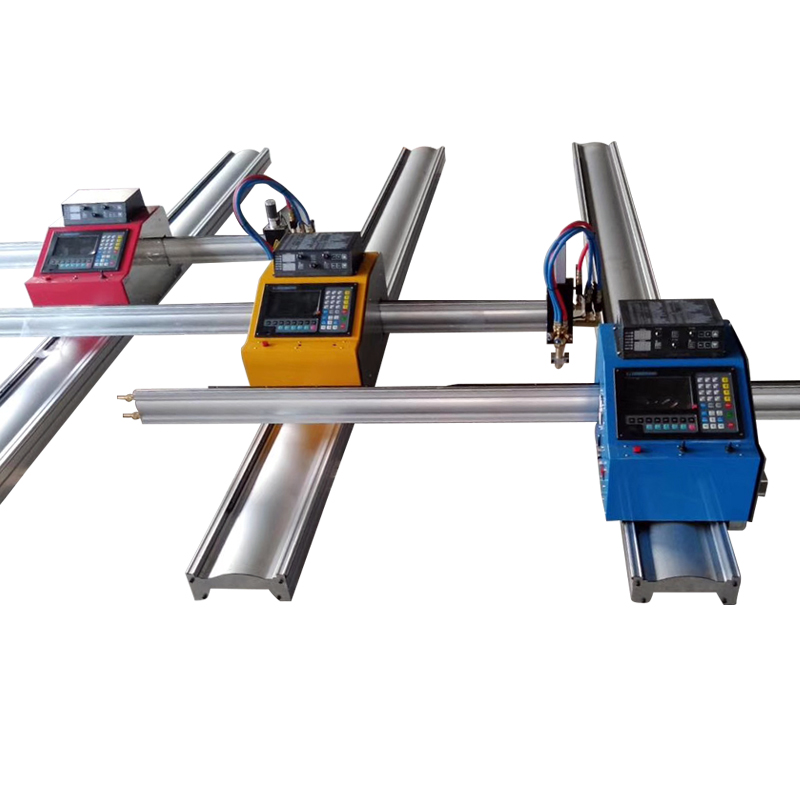

2. What kind of mechanical equipment is CNC plasma cutting machine?

The portable cnc plasma machine mainly uses the heat of the high-temperature plasma arc to make (and evaporate) the metal part or part of the workpiece at the incision, and uses the momentum of the high-speed plasma to remove the molten metal to form the incision. With different working gases,the portable cnc plasma machine can cut various Oxygen cutting of metals that are difficult to cut, especially for non-ferrous metals (aluminum, copper, titanium, nickel), has a better cutting effect, and the portable cnc plasma machine is widely used in automobiles, locomotives, pressure vessels, chemical machinery, nuclear industry, general machinery, construction machinery, steel structure and other industries.

The portable cnc plasma machine is a plasma cutting machine controlled by numerical control technology. Due to the wider range of plasma cutting and higher efficiency, the fine plasma cutting technology has approached the quality of laser cutting in terms of material cutting surface quality, but the cost However, it is far lower than laser cutting, which promotes the gradual development of plasma cutting technology from manual or semi-automatic to numerical control. CNC plasma cutting machine is a high-tech mechanical equipment integrating numerical control technology, plasma cutting technology and inverter power technology.

Third, the characteristics of CNC plasma cutting machine

The portable cnc plasma machine can cut workpieces with complex shapes. the portable cnc plasma machine has the characteristics of fast cutting speed, high efficiency, good cutting surface quality, accurate cutting size, and small thermal deformation of the workpiece, and the cut parts can be directly welded without machining. and application. However, the portable cnc plasma machine should also be noted that the CNC plasma cutting machine uses plasma arc for cutting. Compared with oxygen cutting, the portable cnc plasma machine still has certain defects, which are mainly reflected in the large inclination of the cutting surface, and the finish is not as good as oxygen cutting.

Post time: Jul-22-2022