Factory wholesale Pipe Cutting Laser - China high accuracy tube laser cutter machine – HaiBo Detail:

Tube laser cutter machine description

The Tube laser cutter machine realizes the cutting of two different materials shapes on the same machine. The laser pipe cutting machine adopts a cast iron bed, a rack and pinion drive system, and a professional cutting CNC system, and it is easy to operate and simple to maintain. Besides that the strict assembly process ensures the stable operation of the fiber laser tube cutting machine with high precision. It with imported top-grade accessories, which provides users with powerful cutting ability and efficiency. Therefore the tube laser cutter machine is the best choice for the economical plate and pipe processing.

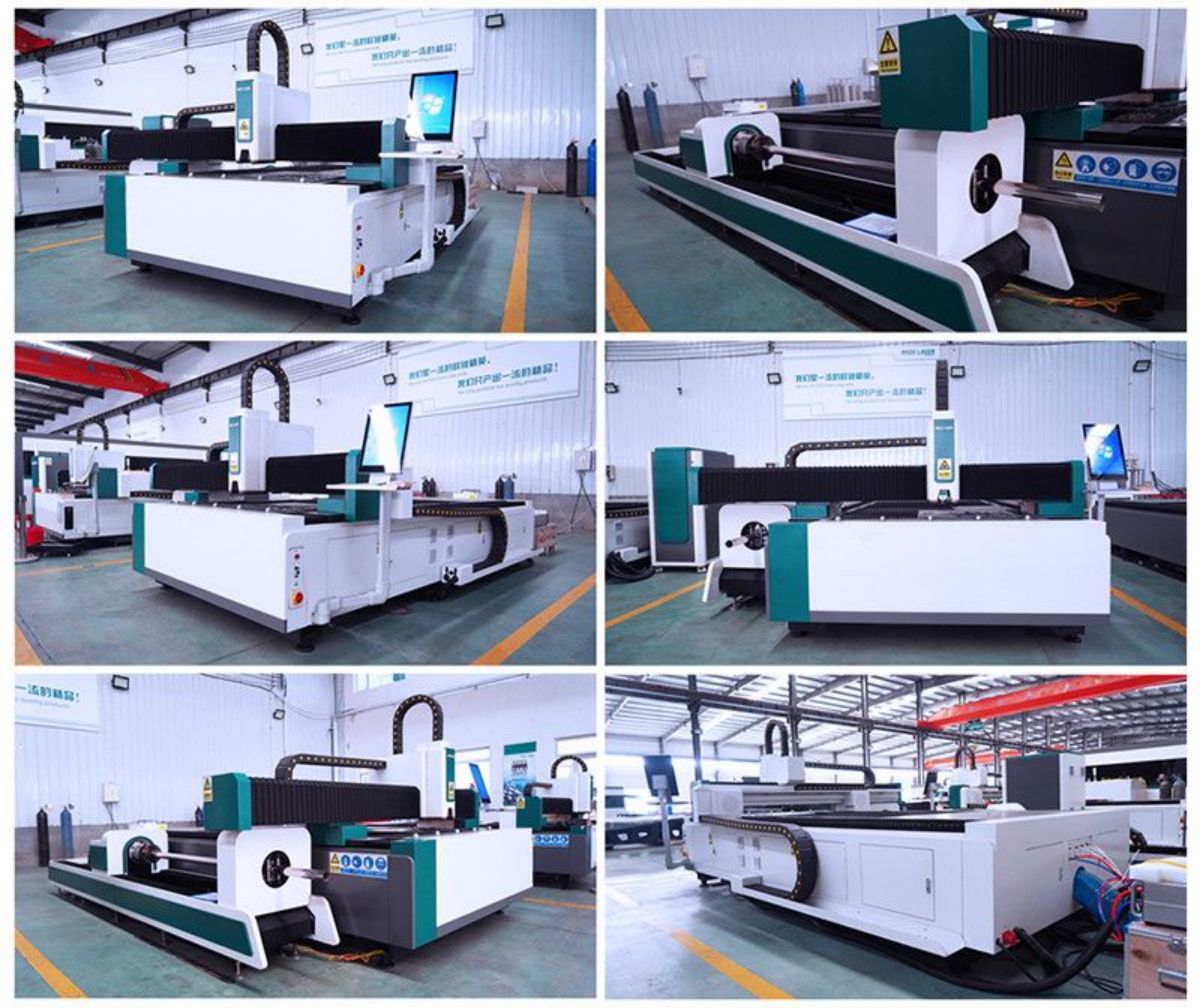

Tube laser cutter machine detailed images

| Model | FH 3015T | FH4020T | FH6020T | FH6025T |

| Working Area | 1500*3000mm | 4000*2000mm | 6000*2000mm | 6000*2500mm |

| Applicable Materials |

Stainless steel, carbon steel, copper, aluminum etc. |

|||

| Materials Thickness |

±0.03mm |

|||

| Accuracy of Positioning |

±0.02mm |

|||

| Laser power |

1000w/1500w/2000w/3000w/4000w/6000w |

|||

| Laser source |

IPG/MAX |

|||

| The length of the pipe |

3m/6m |

|||

| Max. Movement Speed |

140m/min |

|||

| Max Acceleration |

1.5G |

|||

Tube laser cutter machine main configurations

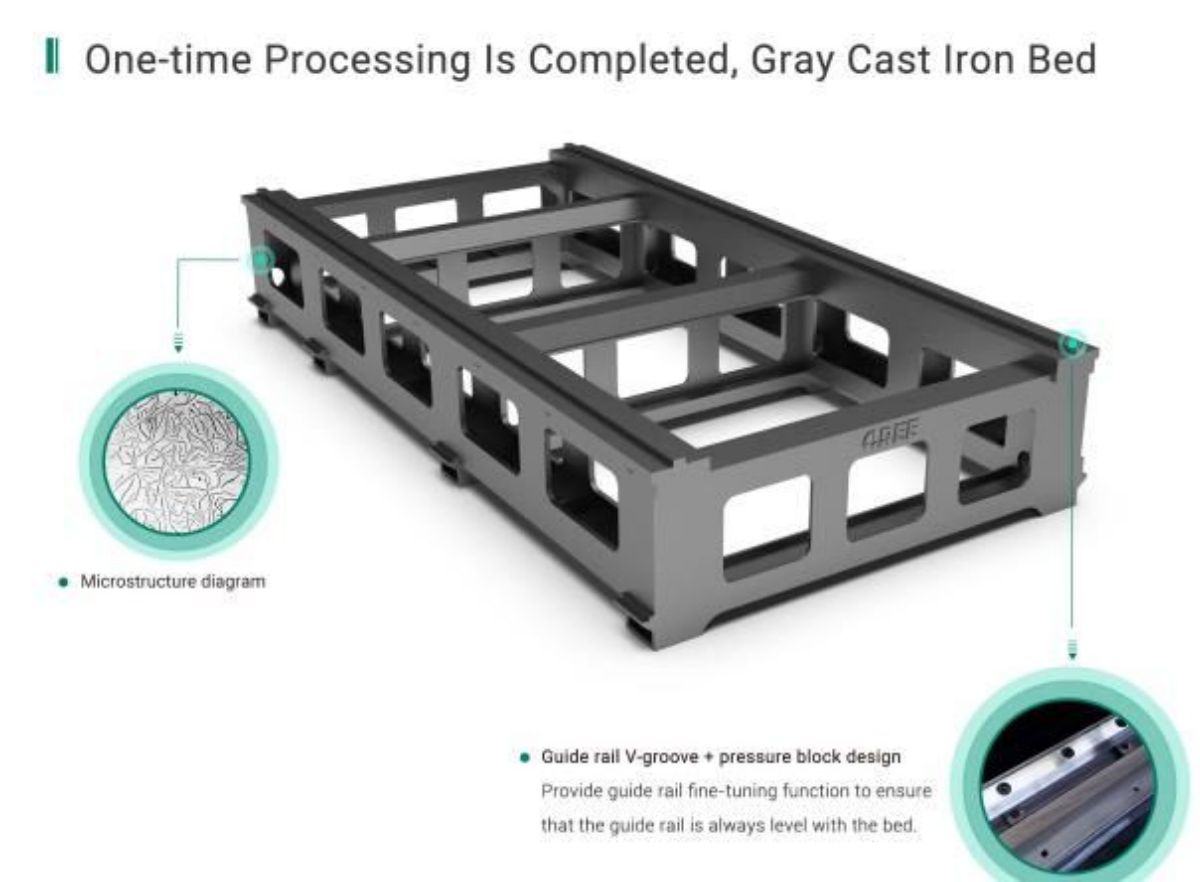

One-time processing is completed, gray welding bed of Tube laser cutter machine

● Guide rail V-groove + pressure block design-Provide guide rail fine-tuning function to ensure that the guide rail is always level with the bed.

● Microstructure diagram-The flake graphite is evenly distributed.Due to the presence of graphite, the Tube laser cutter machine with a cast iron bed has better shock absorption and wear resistance than ordinary fiber laser machine for sale to ensure that it can withstand a large amount of shock and vibration during operation.

● Low notch sensitivity-The material characteristics of the cast iron bed itself make the notch sensitivity lower, and there will be no changes due to the bed notch, and the body performance is more stable.

● Stress annealing process-The whole bed adopts stress annealing treatment method, the internal stress is almost zero, reducing the tendency of warping and cracking, and the bed will not deform after 50 years of use.

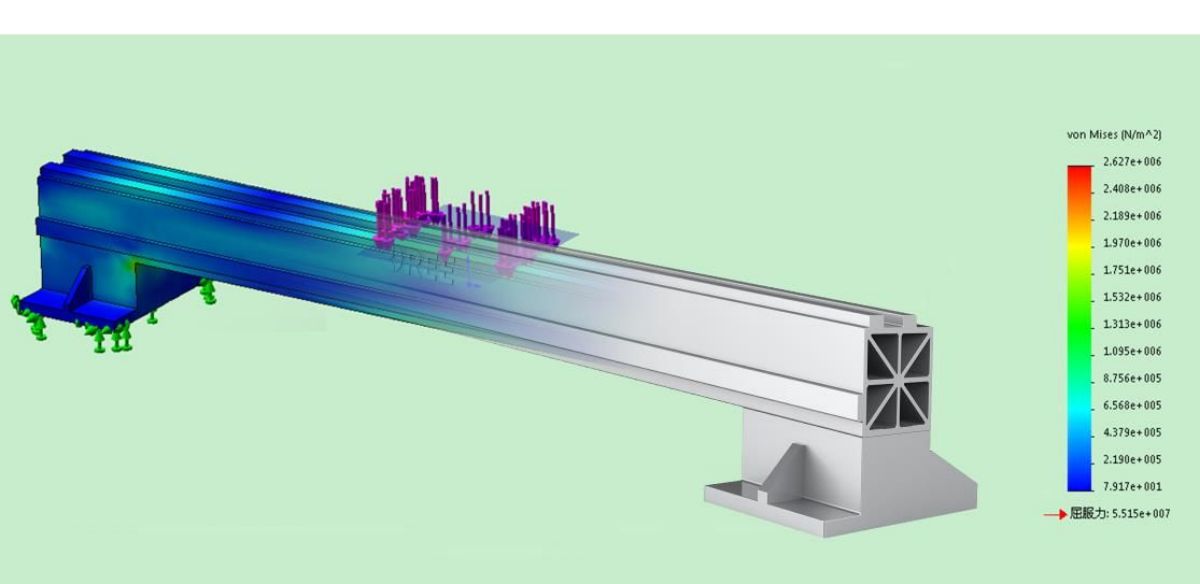

The fifth-generation aviation aluminum beam of Tube laser cutter machine

● T6 heat treatment process-The whole is processed by T6 heat treatment process to make the beam obtain the highest strength.

Solution treatment increases the strength and plasticity of the beam, and improves the corrosion resistance of the alloy; complete artificial aging makes the beam obtain the maximum strength (tensile strength), and obtains the hardness and ductility by controlling the effective temperature and holding time.

● Stop structure-The beam is specially equipped with a “stop structure”,

the convex stop and the concave stop are tightly locked, and the strong stop of the side wall is on the inner side to resist external forces. The overall structure can ensure that the beam does not move, and the structure is stronger.

● Lightweight and high speed-newly developed and upgraded mass-produced beams optimize and reduce their weight while ensuring structural stability, ensuring their ultra-high response speed for Tube laser cutter machine

Automatic focusing laser head of Tube laser cutter machine

● Quick piercing -The laser head adopts two-point centering adjustment, and the focusing is driven by an imported motor, which significantly improves the efficiency in perforation.

● Laser head follow-up function-Follow the change of the height of the board, don’t worry about the unevenness of the board affecting the cutting effect.

● The laser head is made of high-quality materials in accordance with advanced technology. It is strong and durable: it can achieve “online” measure ment during the production process, and the measurement is accurate and rapid.

● Long service life-The protective lens is continuously monitored; the internal structure of the laser head is completely sealed to prevent the optical lens from burning due to dust.

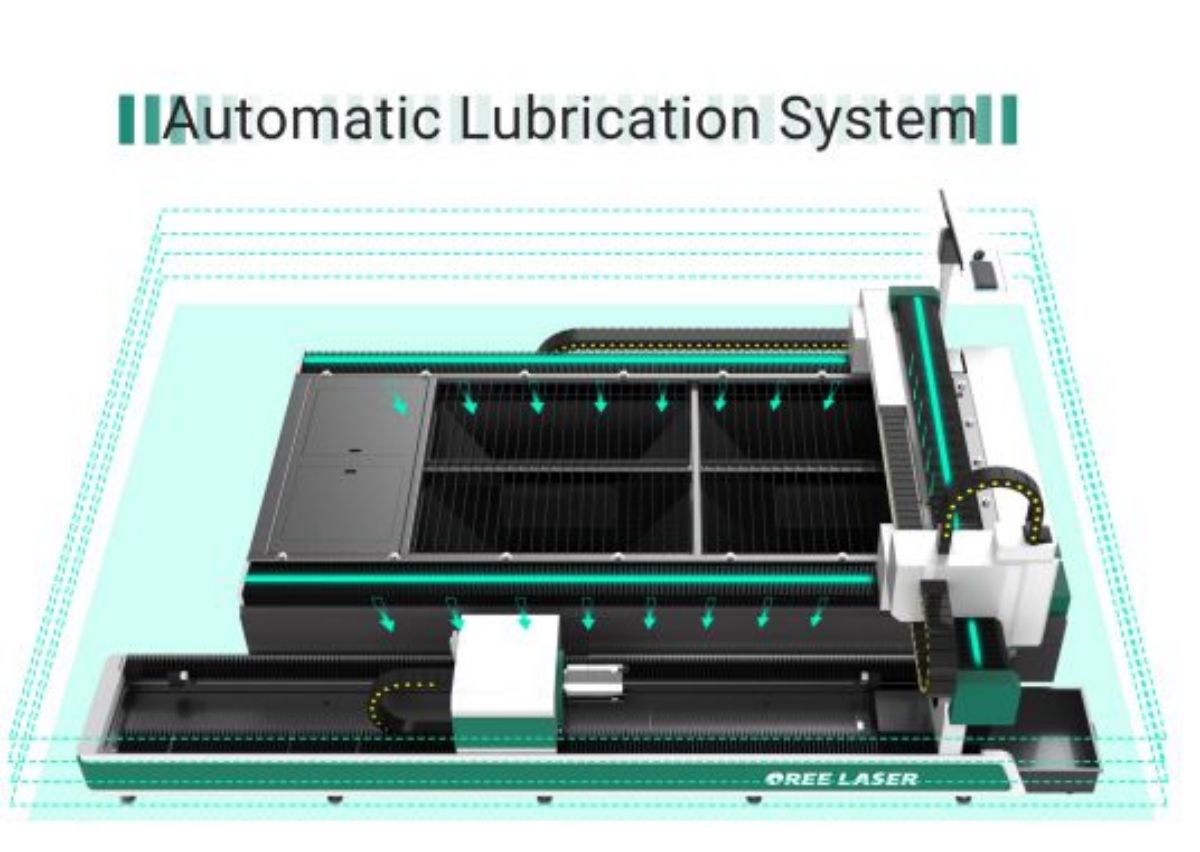

Automatic lubrication system of Tube laser cutter machine

Whole body layout, automatic lubrication of guide rails and racks

● Automatic lubrication-The software controls the oil pump to automatically perform multi-point lubrication, and the lubrication times and time intervals are manually controllable, saving labor time

● Multi-point lubrication-Automatic lubrication system for automatic lubrication of guide rails, sliders, screws, racks and other points, reducing equipment strain rate

● Waste oil recycling-Specially set oil return tank, which can recycle and centrally dispose of lubricating waste oil. Humanized design ensures the cleanliness of the equipment body

Cypcut plane control system of Tube laser cutter machine

● Edge finding aid-Dual-drive deviation self-correcting two-stage capacitive edge seeking, accurately locates the edge of the plate, saves time and materials, and improves the utilization rate of the plate.

● Concise and clear process settings-After importing graphics, you can quickly complete the setting of the entire board process; support three-level perforation and automatic layout.

● Double drive deviation self-correction-Using the gantry synchronization function, the deviation of the dual-drive shaft will be corrected every time the origin is returned to ensure the cutting accuracy.

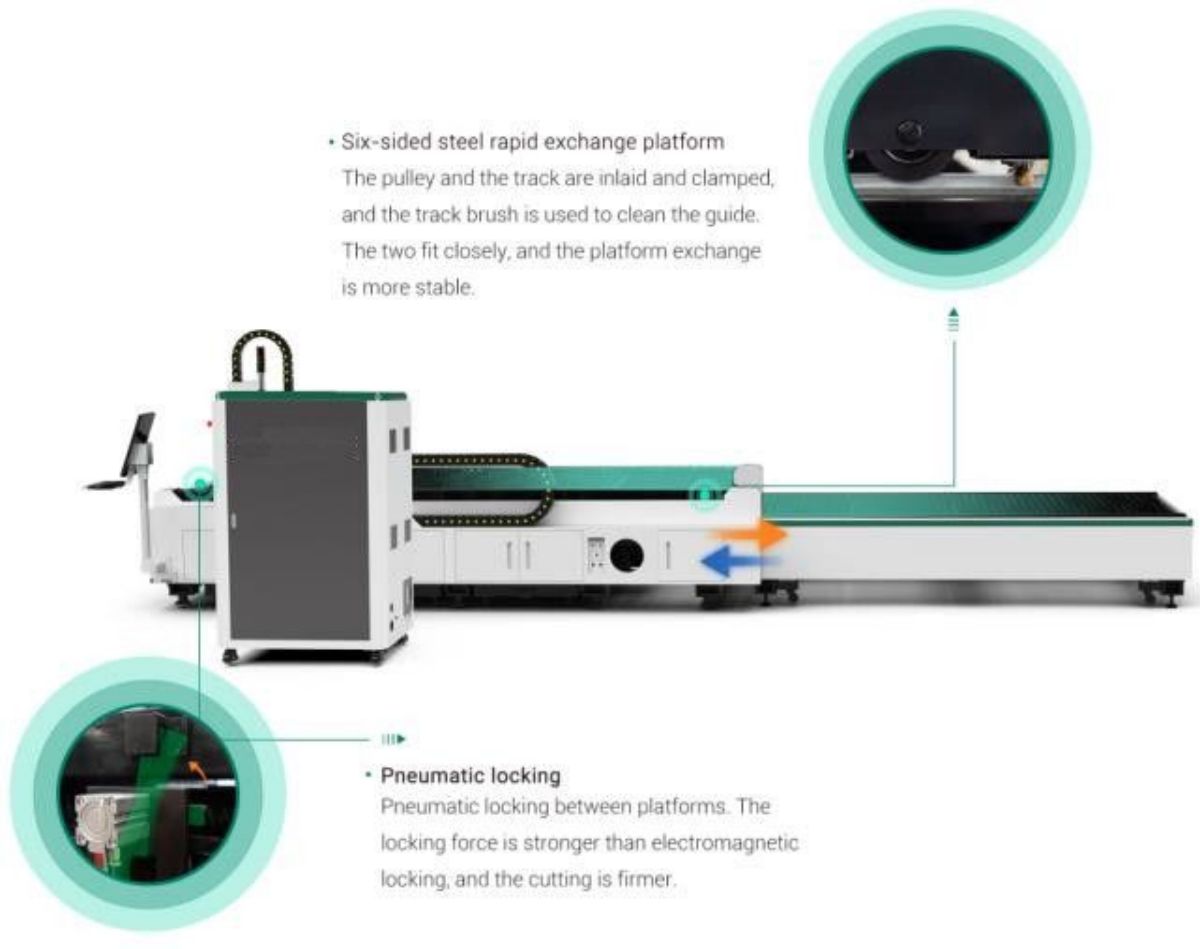

Six-sided Steel Rapid Exchange Platform for Tube laser cutter machine

● Single Platform Exchange Only Takes 10 Seconds-Taking the 3015 platform as the standard, a single platform exchange only takes 10 seconds, which can effectively improve the processing efficiency of the manufacturer.

● Burn-proof Partition -Prevent sparks from burning the dust cover and reduce loss.

● Reinfoecrment of Knife Strip-Prevent plate vibration during processing and improve cutting accuracy.

● Heightening The Sheet Metal-The sheet metal on both sides of the exchange platform is heightened ,and the platform pulley is built in for saler.

Tube laser cutter machine cutting samples

Tube laser cutter machine packages and shipping

Service Team& feedback

1. 24 hours Quick Feedback;

2. “Training Video”, “Instruction Book”, and “Operation Manual” will be offered;

3. Brochures for simple trouble-shootings of the Tube laser cutter machine is available;

4. Plenty of technical support online is available;

5. Quick Back-up Parts Available & Technical Assistance;

6. Free training service is available.

7. Warranty for the Tube laser cutter machine is 3 years

Product detail pictures:

Related Product Guide:

Our concentrate on is always to consolidate and enhance the excellent and service of present solutions, in the meantime regularly develop new products to meet distinctive customers' demands for Factory wholesale Pipe Cutting Laser - China high accuracy tube laser cutter machine – HaiBo, The product will supply to all over the world, such as: Frankfurt, Norway, India, When It produced, it making use of the world's major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a "people-oriented, meticulous manufacturing, brainstorm, make brilliant" company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we'll be delighted to serve you.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

-

Hot New Products Cheap Cnc Plasma - Portable c...

-

Factory wholesale High Definition Plasma Cutter...

-

Factory wholesale Fiber Laser Cutting Machine M...

-

Wholesale Cnc Plasma And Router Table - 2022 H...

-

Cheap price Portable Cnc Plasma Cutting Machine...

-

Manufacturing Companies for Metal Cutting Table...