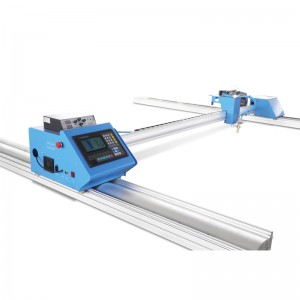

- small plasma cutter Introduction

The design of the small plasma cutter is beautiful and generous, high-speed and accurate, easy to operate, and extremely efficient. The longitudinal and cross beams of the small plasma cutter are welded and formed by high-strength section steel. Vibration aging and natural aging treatment eliminate welding stress, and a large machining center is used for one-time use. Planing and forming ensure the accuracy of the machine tool; the structure of the machine tool has been strictly tested and verified to meet the use of various complex environments.

The small plasma cutter can meet the cutting and blanking of various metal plates of different thicknesses by installing different functional components and different cutting torque systems; the small plasma cutter is designed with humanized ergonomic principles, with a simple appearance, solid and durable, stable operation and accurate positioning to meet high-quality cutting requirements.

2.The Performance Characteristics of the small plasma cutter

The performance characteristics of the small plasma cutter

◆ The PC-based CNC control system can cut various complex patterns. The movable and user-friendly operation console design and the dialogue-type human-machine interface make the operation of the machine simple and easy, and the requirements for operators are lower.

◆ All mechanical parts have been precisely processed to ensure smooth and noiseless operation of the whole machine, which not only improves the precision of the machine tool, but also prolongs the service life;

◆ No requirements for placement and working environment, suitable for harsh industrial sites, only need cleaning and no maintenance.

◆Easy to install, the length of longitudinal guide rail can be customized by customers to cut slender workpieces;

◆ High-precision automatic control of the torch height keeps the distance between the torch tip and the steel plate constant, which ensures the safety of the torch.

3. Main Technical Parameter of the small plasma cutter

|

No |

Item |

Technical parameter |

|

01 |

Effective cutting width |

2300mm |

|

02 |

Effective cutting length |

6000mm |

|

03 |

Flame cutting thickness (mm) |

Perforation cutting: 60mm Edge cutting: 160mm |

|

04 |

Plasma cutting thickness (mm) |

Optional by cutting thickness |

|

05 |

Torch lift stroke (mm) |

1-150 |

|

06 |

Machine running speed(mm/min) |

50-6000mm/min |

|

07 |

Set speed error (%) |

≤±1% |

|

08 |

Automatically adjust high precision (mm) |

≤±1.0mm |

|

09 |

Straightness of main rail |

≤±0.2 mm/10m |

|

10 |

Longitudinal levelness of main rail |

≤±0.2mm/10m |

|

11 |

Levelness between two rails |

≤±0.5 mm/10m |

|

12 |

Parallelism between two rails |

≤±2 mm/gauge |

|

13 |

Scribing accuracy and overall accuracy of the whole machine (Subject to the right comprehensive graph) Side length (four sides) 1000╳1000mm Scribing speed 500-800mm/min |

|

|

14 |

Side length error (four sides) |

≤±0.5 mm |

|

15 |

Diagonal error |

≤±0.5 mm |

|

16 |

Back to origin deviation |

≤±0.2 mm |

|

17 |

Diagonal straightness |

≤±0.3 mm |

|

18 |

Intersection deviation |

≤±0.5 mm |

|

19 |

Straight line deviation |

≤±0.2 mm |

- The Details introduction of the small plasma cutter

4.1 The small plasma cutter has Bilateral drive design

Stable operation at high and low speeds, stable cutting without shaking

4.2 The small plasma cutter using thick aluminum alloy material

Thick aluminum alloy material, stable performance without deformation

Light weight, convenient for packaging and transportation

4.3 The small plasma cutter’s CNC Control System

Shanghai Fangling F2100 system is an advanced CNC system for flame, plasma, high-pressure water jet, and laser cutting machines developed by Shanghai Jiaotong University especially for our company. Interface design of the system, cutting speed and motion control combine advanced technology domestic and abroad, comprehensive process performance, convenient operation, and it is a certain intelligent system in cutting processing.

1) The system has a highly reliable design and has the ability to resist plasma interference, lightning strikes, and surges.

2) Practical flame/plasma cutting process, when plasma processing, automatically complete corner speed control, and height controller control.

3) It has the function of slitting compensation, and detects whether the compensation in the program is reasonable, and makes a corresponding report for the user to choose

4) Breakpoint recovery, automatic power-off recovery function, automatic memory of breakpoints

5) Arbitrary segment selection and perforation point processing function

6) It has the function of epitaxial perforation suitable for thick plates and bridging function suitable for thin plates

7) Rewind, segment selection, breakpoint recovery, optional perforation position and other functions, which greatly facilitates the user's manipulation;

8) Can transfer cutting at any time

9) Adopting special small line segment processing function, smooth walking, can be widely used in metal cutting and advertising, iron art, etc.

10) Including 24 types of graphics (expandable and customizable), including commonly used basic machining parts

11) Fully compatible with various nesting software, such as: IBE (Germany), FASTCAM, etc.

12) Chinese and English operation interface conversion, dynamic graphic display, 1 to 8 times graphic magnification, automatic tracking of moving points, using U disk to read programs and timely software upgrades.

4.4 Automatic Programming Nesting Software Has 61 Basic Graphics

Each type of graphics can be arbitrarily edited in size and quantity of cutting metal

The development of STAR CAM cncCut is to meet the requirements of enterprises: it has many functions and is easy to operate. This software is suitable for various cutting methods, such as: water jet cutting, flame cutting, plasma cutting and laser cutting, etc., no need to load other software.

4.5 The small plasma cutter equipped Arc voltage height controller

Automatic lifting, protecting nozzle, simple operation

4.6 The small plasma cutter’s cutting mode

Suitable for flame and plasma cutting,reducing secondary processing and improving production efficiency

4.7 The small plasma cutter equipped Nylon drag chain

This machine using reinforced nylon drag chain, high temperature resistance, low temperature resistance, stable performance, long service life.

The small plasma cutter Plasma Cutting Effect

The small plasma cutter Flame Cutting Effect

6.After-sales Service

1) After check and acceptance by clients, the warranty period is 1 year.

(2) During 1-year warranty period, Yomi provides free repair service in case of

failure due to defective part/ component, and replaces defective part or component free of charge. Transportation costs are borne by clients ,such as express fees.

(3)During the 1-year warranty period, when we get maintenance call ,we will reply within 8 hours, and set up a 1:1 chat group on WhatsAPP or QQ to follow-up, through video and Computer remote control etc, guide the customer to solve the fault or replace accessories.

If clients need on-site repair, Yomi will arrange the overseas engineer ( usually 1 person ,can speak English) immediately; the traffic, Visa, air ticket, food, accommodation, translation, internet, overseas allowance etc for Yomi engineer should be borne by clients.

(4) After the warranty period, the replacement parts will be charged at the cost

price. Transportation costs are borne by clients, such as express fees/air costs.

(5) Controller system and software will be upgraded free of charge.

(6) Except for human damage for machine, Yomi supply life-long maintenance service.

7.Customers Site Display for the small plasma cutter

8. Packing&Shipping for the small plasma cutter