Advantages

► 100% (40℃)duty cycle;

► Cutting current is continuously adjustable, suitable for welding both thin and thick plate;

► It will stop cutting automatically when lack the Air pressure or hydraulic pressure to protect the torch from burnt;

► There are arc sync signal and arc voltage signal connector which are easy for auto cutting and especially suitable for matching with numerical control machine and robot;

► Cutting current upslope can be adjusted to prevent damages of nozzle and electrode;

► Arc striking signal, arc pressure signal, air supply control and arc pressure output function makes it specially suitable for CNC and robot cutting;

► Two machines parallel use is available, double the output current to cutting extra-thickness material well;

► Machine used setting, digital display makes it specially suitable for machine and robot using.

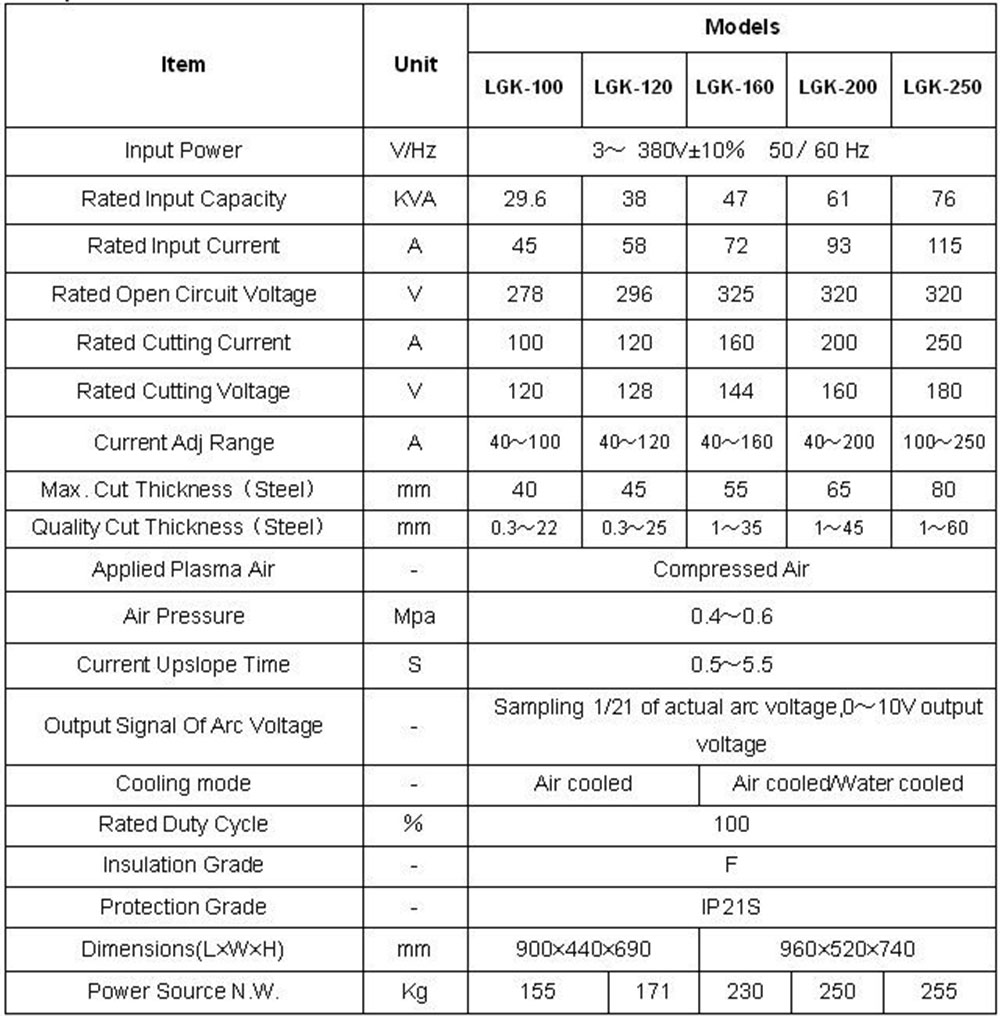

Main Parameters

2. Plasma gas conditions

Work pressure range:0.4MPa~0.6MPa

Gas supply pipe compression strength :≥1MPa

Gas supply pipe inner dimension:≥Φ8

Gas supply flux:≥180L/min

Filter water from gas and then put it into cutter

Work principles

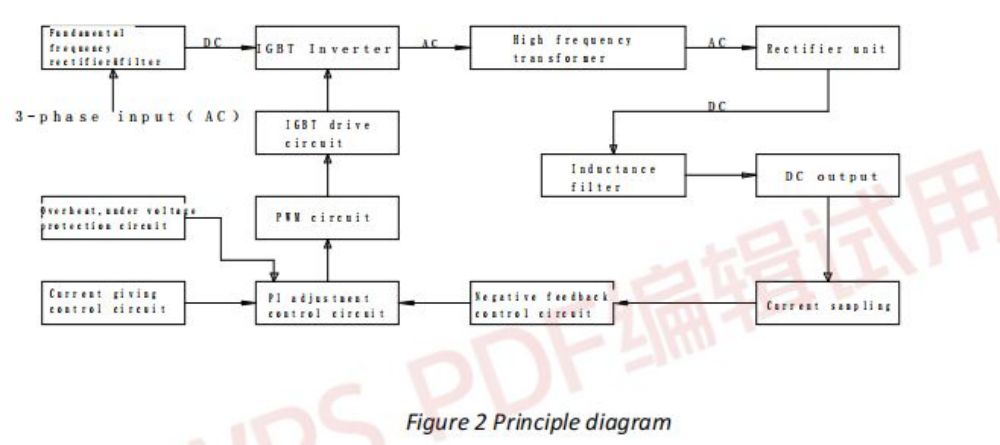

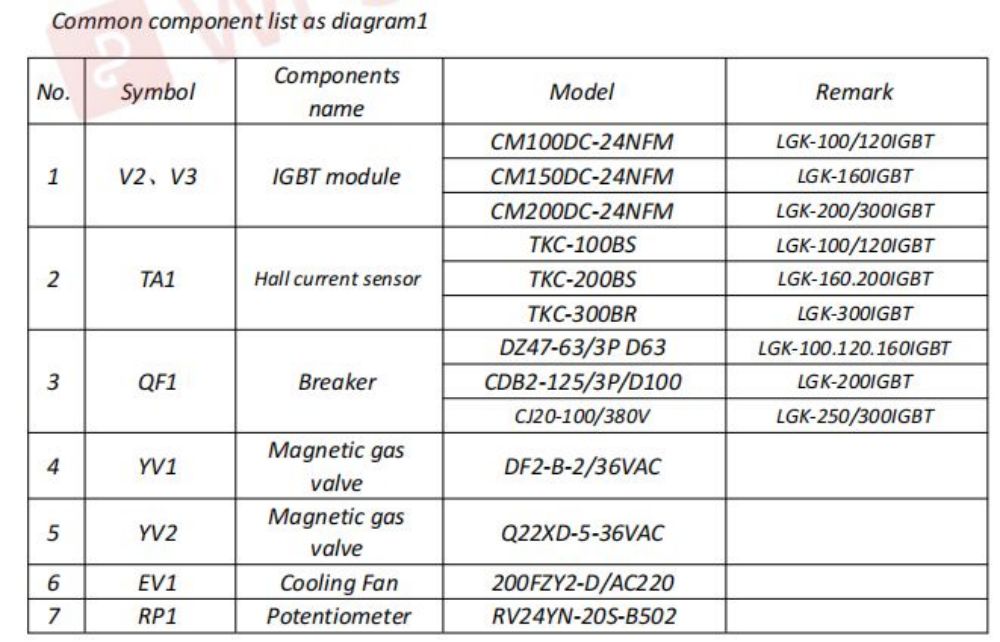

The control circuit of cutting machine adopts advanced electronic part IGBT as the main inverter switch component. Three-phase AC power is converted to 20KHz high-frequency DC current after being rectified by three phase rectifier. Then under the function of IGBT inverter the DC current is inverted to AC high frequency current, which is inverted to DC current after experiencing voltage reduction in high frequency transformer, current rectifying in fast recovery diode. This DC current is filtered through reactor, and the output cutting current is obtained.

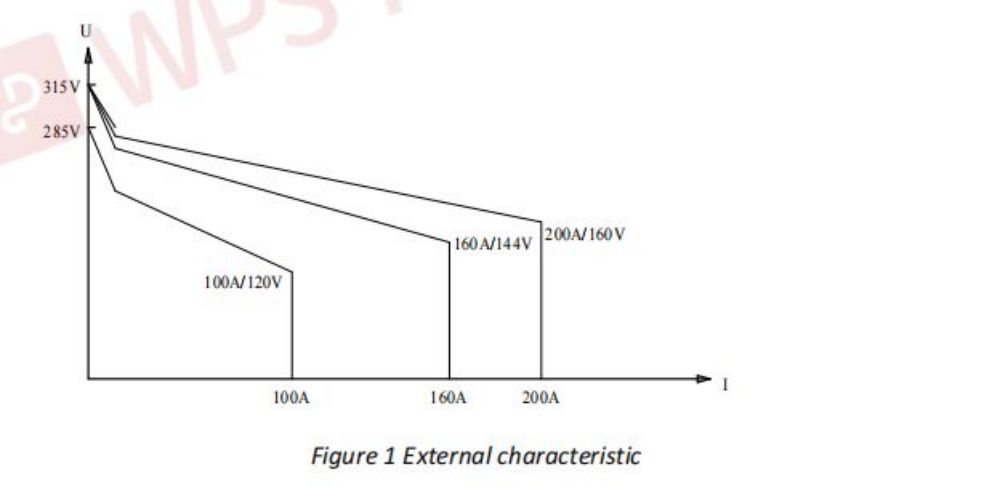

Control circuit can control output current by controlling driven pulse width. The real time cutting current, which is obtained through current sensor connected to output terminal in series, is used as negative feedback control signal. After comparing with current adjusting signal, the negative control signal is sent to PWM adjusting integrated circuit, then a controlled driving pulse is output to control IGBT. Thereby a constant output current can be maintained, and a steep dropping & constant current external characteristic is obtained. Striking arc adopts high-frequency striking model. The main circuit refers to appendix figure1,and principle diagram of control circuit is shown as figure 2.

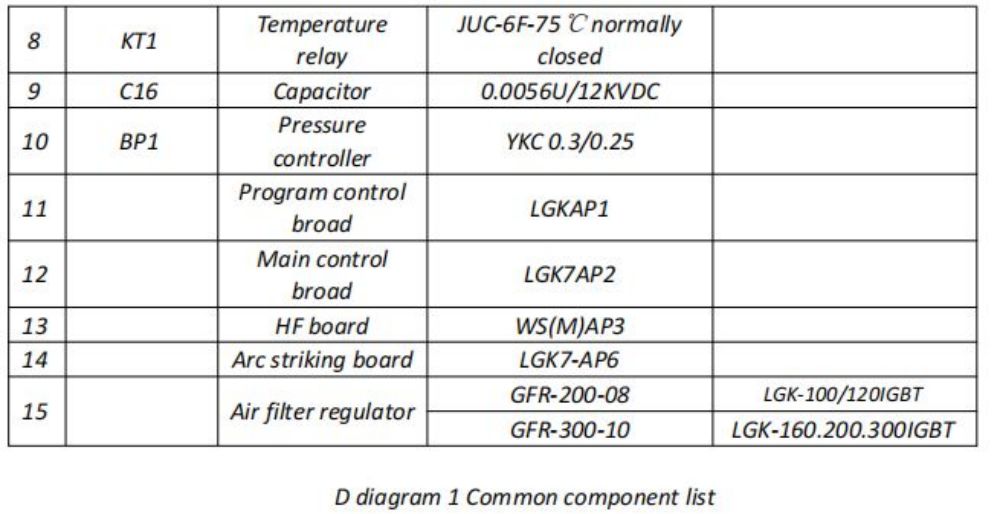

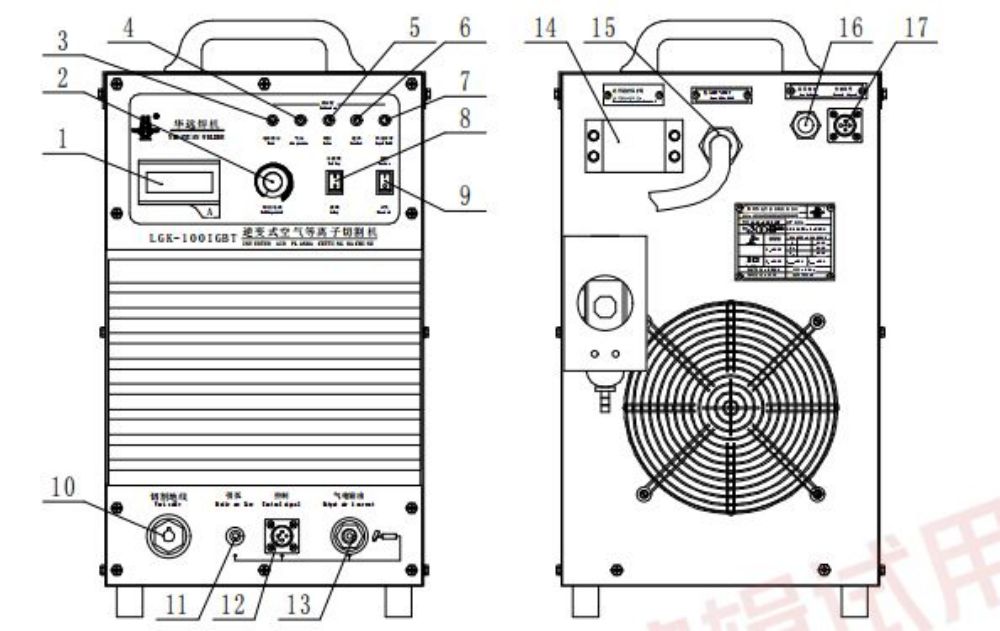

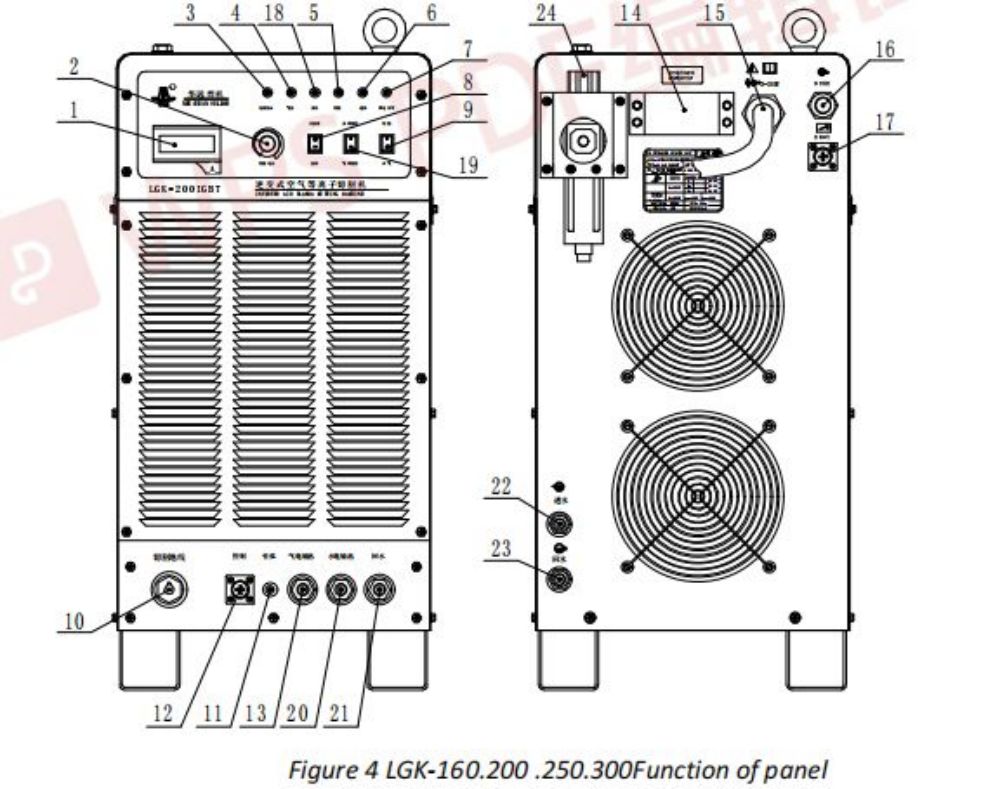

Panel and its functions(LGK-100 see Figure 3, LGK-160/200/250/300 see Figure 4)

1.Digital ammeter: Displaying pre-set cutting current before cutting, displaying cutting current when cutting

2.Cutting current adjusting knob: Adjusting cutting current

3.Power indicator lamp: Indicating if the cutter is energized.

4.Air pressure indicator lamp:It is ON when the pressure of compressed air exceeds 0.2Mpa. It is OFF when the pressure is less than 0.15Mpa.

5.Cutting indicator lamp: When the lamp ON means the cutting machine has started.

6.Overload indicator lamp: It is ON when the cutter is over loaded (generally it is on when cooling fan is damaged.)

7.Input fault indicator lamp: It is ON when power source misses phase or it is less than 330VAC.

8.Gas control selection switch: When it switches to Check air, gas valve opens to test gas flux. When it switches to Cutting, the gas valve opens during cutting automatically.

9.Torch operation mode selection switch: When it turns on 2-Step, the torch switch should be pressed at the process of cutting, and the cutting comes to stop after loosening the switch. When it turns on 4-Step, press the torch switch and loosen it, the cutting starts to work, and comes to stop after pressing the switch again.

10.Cutting ground wire outlet: To connect cutting ground wire

11.Torch Pilot terminal: To connect torch pilot wire.

12.Torch control outlet: To connect torch control signal wire.

13.Air & Power output terminal: the current output terminal is also the compressed air output terminal. It is gas pipe connector to connect water-cooled torch when the water-cooled torch is used, and it is connector to connect torch gas-cooled cable when air-cooled torch is used.

14.Spare wire hole for arc voltage output: the arc voltage output wire is not connected when the machine is finished. If it is needed, please open the cutter top cover, and use two-core wire to connect the wire terminal on printed board LGK7-AP5, which has two kinds of output signal, one is the 1:1 output and the other is 1:20 output, please Figure 3 LGK-100 Function of panel connect the wire according to the requirements, and pay attention to the negative and positive electrode.

15. Control signal connector: To control automatic cutting equipment

16. Power source switch: Control the ON/OFF of 3-phase power supply of cutter

17. Air pressure regulation filter:For adjusting work pressure of compressed air and filtrating water from air

18. Hydraulic pressure indicating lamp: connect the cooling water supply, when water current is bigger than 0.45L/min, the lamp will be on.

19. Gas-cooled torch/water-cooled torch selection switch: gas-cooled torch is used only when it switches to gas cooling, and water-cooled torch is used under water cooling mode selected.

20. Water/Power output terminal: the cutting current output terminal is also the water output terminal, it is used to connect the water cooling cable.

21. Backwater terminal of the torch: It is used to connect the water recycle pipe.

22. Backwater terminal: it is used to connect the water tank recycle pipe.

23. Water input terminal: it is used to connect the water tank output pipe.